Best molding machine manufacturer : Top 5 Benefits for Molding machine manufacturing 2025 Guide

In the world of modern manufacturing, efficiency and precision are everything. best molding manufacturer machine From data cable production to electronics and plastic accessories, businesses depend on the reliability of their machines to maintain quality and meet growing demand. One machine that plays a critical role in this process is the best molding machine manufacturer.

Choosing the best molding machine isn’t just about price—it’s about performance, durability, and long-term value. With so many options available, it can feel overwhelming to decide which one suits your business. This guide will help you understand what molding machines are, why they matter, and how to select the right one for your industry.

Who is the best molding machine manufacturer of manual hand molding machines?

A molding manufacturer machine is an industrial device that shapes raw materials like PVC, ABS, or rubber into finished products. These machines are essential for industries. such as

1. electronics and data cables (data cables, charging cables, and HDMI connectors).

2. Automotive components.

3. consumer goods and accessories.

4. packaging and household items.

The machine uses molds to give raw material its final form. In cable manufacturing, for example, the machine ensures connectors are shaped perfectly. providing both strength and durability.

Type of molding machines/Best molding manufacturer machine.

- Manual hand molding machines.

Designed for small businesses or startups.

Affordable and easy to operate with minimal setup.

Requires skilled labor for consistent output.

Suitable for limited production runs or custom orders.

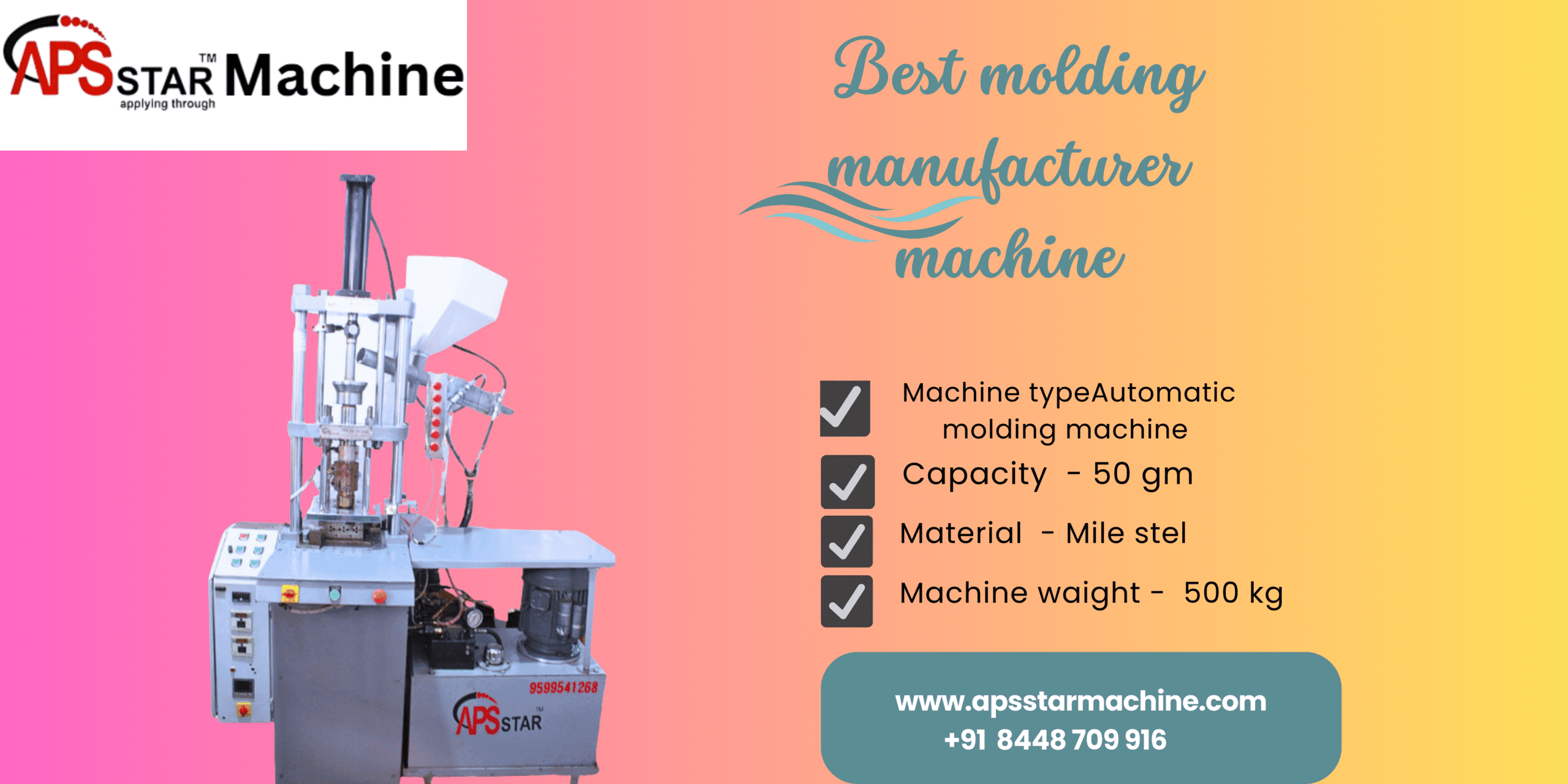

2. Automatic molding machines.

Best for medium- to large-scale production.

Offers higher speed and precision with minimal labor.

Consistent results reduce product defects.

Ideal for businesses aiming to scale and meet larger orders.

Why the Right Machine Matters

Investing in the right molding machine can directly impact your business in several ways:

Quality Assurance—precise molds lead to uniform products. reducing customer complaints.

Production speed—faster machines increase output and reduce lead times.

Cost Saving—Energy-efficient models cut electricity bills, while durable machines reduce maintenance costs.

Customer trust—high-quality products build long-term brand loyalty.

For example, in fast-charging cable manufacturing, a poorly molded connector may break easily. leading to negative reviews. A high-quality molding machine ensures every connector is durable and reliable.

Table of Contents

Features of the Best Molding Machine Manufacturer’s Machine

When looking for the best molding machine, consider these key features:

High-precision molds—Ensures uniformity in every product.

Energy Efficiency—Low power consumption without compromising speed.

Durable Build Quality—Made with robust materials for long-term use.

User-friendly controls—simple interface and automatic features.

Customization options—adjustable settings for different product requirements.

Manual vs Automatic: Which One Should You Choose?

Manual Hand molding machines;

Affordable investment.

Suitable for startups or small orders.

requires skilled labor.

Automatic molding machine:

Higher upfront cost but long-term savings.

Minimal labor required.

Perfect for bulk production.

consistent quality and high output.

👉 If your business is scaling, automatic molding machines are the smarter investment.

How to select the Best Molding machine for Your Business

Identify Your Product Needs—Daily Output Requirements.

Set a budget—balance cost vs. long-term ROI.

Check compatibility—Ensure the machine supports your raw materials (PVC, ABS, etc.).

Looking for warranty support—after-sales services matter.

Consider Future Growth—Choose a Machine That Can Scale with Your Business.

Final thoughts

The best molding machine manufacturer is not just about price—it’s about efficiency and durability. and support.

Whether you choose a manual model for a setup or an automatic one for mass production, investing in the right machine ensures long-term success.

If you’re in the data cable or charger industry, upgrading to a reliable molding machine can dramatically improve product quality and customer satisfaction.

| Manufacturer | Location (state / city) | Tonnage/Range | Technology Type Offered | strengths/unique selling points |

| Windsor machine limited | Ahmedabad, Gujarat | Wide range, from medium to large tonnage machines (50-4000+ tons) | Hydraulic, electric, hybrid; also two-platen machines (via collaboration) | Strong heritage; large installed base; good for heavy-duty molding; versatile for various industries (automotive, packaging, etc.) |

| Futech machinery Pvt. Ltd. (formerly B.S. Technologies) | Bahadurgarh, jhajjar, Haryana | From 7 Ton up to – 1100 tons capacity | Hydraulic and toggle machines | The range covers very small to large; good for both light and heavy parts; decent local content and cost advantage. |

| Shibaura Machine India Pvt. Ltd. | India (multiple locations) | High-precision machines suitable for mid- to high-tonnage; exact tonnage depends on model. | servo-hydraulic, all-electric, hybrid, etc. | very good precision; know globally; strong in performance and durability; good for applications which need tight tolerances, etc. |

| Electronic plastic machines limited | Pune (Maharashtra) | Medium range (depends on model), used in many general-plastic jobs. | Likely offers hydraulic/hybrid, etc.; emphasis on energy efficiency and precision | Good local presence, RD capabilities, and good service in western India; decent cost-performance ratio. |

| Pratishna Engineers | Mumbai, Maharashtra | Range of tonnages; focus on servo/hybrid designs, etc. | Likely hydraulic, hybrid and perhaps electric; customized machines | Strong in customization; good market presence; decent for medium-size users who want good efficiency and cost balance. |

| Fero Engineering | Based in India | 15 tons to 1100 capacity | Horizontal and vertical machines, likely both types, certified ISO/CE etc | Fast-growing; relatively newer but good capacity; ability to supply many units; competitive pricing. |

| Milacron India Pvt. Ltd | India-wide (global brand) | Large industrial tonnage; strong for heavy sections, etc. | Advanced machines, high efficiency, and storage in automation, etc. | Global brand, proven reliability, good for large-scale, export, and precision work. Support is likely strong, but cost may be higher.apsstarmachine.com |