Nomatic Molding Machine Price 2025 | APS Star Quality and Buyer’s Guide

If you’re in the plastic or packaging business, the decision of choosing a molding machines can make or break your margins, in 2025 Nomatic Molding Machine Price 2025 | APS Star Quality and Buyer’s Guide” Nomatic molding machine” (also sometime referred to as air / pneumatic / “Nomatic” style machines)from APS Star have gained traction for small-to-medium scale use cases. But what is the going price in 2025? what drives cost? And how do you pick the model that gives the best return?

In this article, we’ll cover:

- What a Nomatic molding machine is (basics)

- Price trends & APS STAR offerings in 2025

- Key factors influencing pricing

- Buying checklist & pitfalls

- ROI & maintenance insights

- Future outlook

Nomatic Molding Machine Price 2025

What is a “nomatic” ( Pneumatic / Air) molding machine?

Before we talk price, it helps to understand what differentiates a “Nomatic” molding machine from other types (hydraulic, electric, hybrid).

- A Nomatic machine typically uses compresses air or or pneumatic actuation to drive movement. The makes it mare energy efficient for lighter-duty operations.

- it is suited for lower tonnage, simpler molds or molds, or small to medium production or small to medium production batches.

- Because pneumatic systems have fewer moving hydraulic parts, maintenance is often simpler — but the trade-off can be in force limits, precision under heavy load, and cycle time.

- Many APS Star nomatic moldels are available in 30-gram and 50 gram capacity versions. For example, APS Star lists a Nomatic molding machine 50 gram 50 gram at ₹64,999. APS Star Machine

- They also have a 30 gram variant listed at ₹49,999 on their site. APS Star Machine+2APS Star Machine+2

Given that, a Nomatic machine is ideal when your product size is within limits, you want lower capital cost and simpler operation, and don’t require extremely heavy clamping forces. Nomatic Molding Machine Price 2025

2025 Price range for Nomtaic Machine

Here’s what APS Star is offering in 2025 nomatic molding machine price for its Nomatic / air / pneumatic machines (as per their product listings):

| Model / Capacity | Type | Price (INR) | Notes |

|---|---|---|---|

| Nomatic 30gram | Air / Nomatic | ₹49,999 APS Star Machine | Entry-level capacity |

| Nomatic 50 gram | Air / Nomatic | ₹64,999 APS Star Machine | Mid-range nominal capacity |

Nomatic Molding Machine Price 2025 (as listed) excluding molds, tooling, shipping, installation or any add-ons.

To put in perspective, APS Star also lists other molding machines (hydraulic, 4-in-1 etc.) in higher ranges:

- A15-ton molding machine: ₹189,999 APS Star Machine

- 4-in-1 hydraulic molding: ₹189,999 APS Star Machine+2APS Star Machine+2

- Fully automatic dona plate machine: ₹74,999 APS Star Machine

So the Nomatic models sit at the lower-to-mid end of APS Star’s portfolio.

Nomatic Molding Machine Price 2025

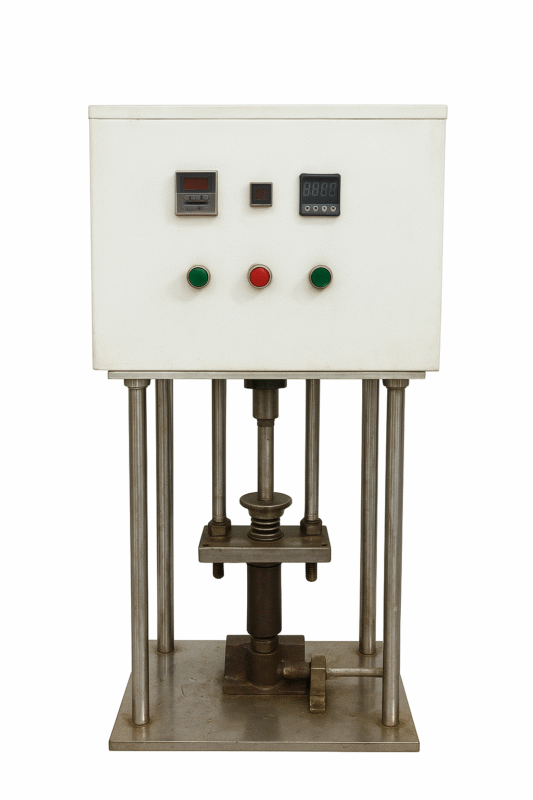

Nomatic Molding Machine 30 gram

Machine type – Air Molding Machine

Capacity – 30 gram

Material – Mild Steels

Machine Weight – 40KG

Price – 49,999.00

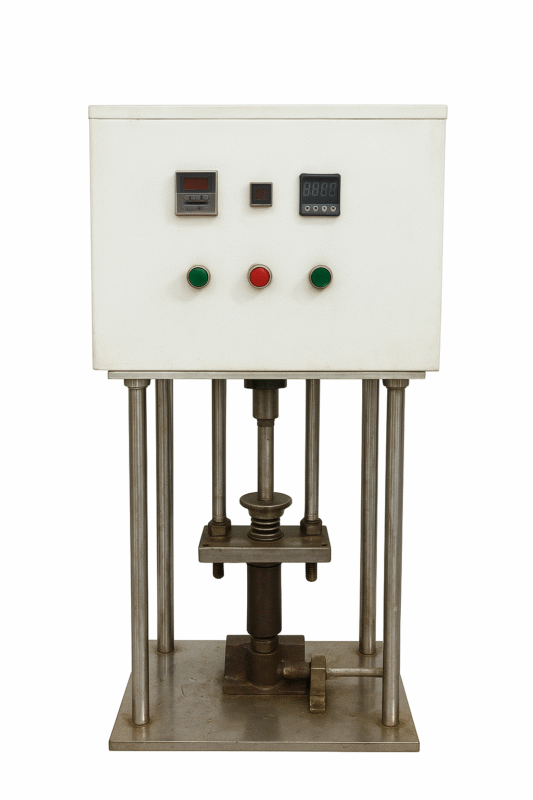

Nomatic Molding Machine 50 gram

Machine type – Air molding machine

Capacity – 50 gram

Material – mild steel

Machine weight – 50Kg

Price – 64,999.00

Why Price Vary – Key Cost Factors

Understanding what derives the cost help you compare quotes and avoid overpaying. Here are the main drivers for Nomatic / pneumatic molding machines: Nomatic Molding Machine Price 2025

- Capacity / Shot size

Moving from 30g to 50 g or higher requires stronger actuators, larger components. - Build quality & material

Use of premium steel, precision machining of joints, quality pneumatic cylinders — these increase cost. - Control system & automation

Even a nomatic machine may have PLC-based control, servo drives, temperature controllers, etc. The more advanced the controls, the higher the cost. - Accessories & add-ons

Mold cooling, feeders, material dryers, conveyors, robotic picker, multi-short capability – each extra module adds incremental cost. - Mold / tooling cost

While the machine is the frame, your mold quality and complexity often dominate overall investment. - Transportation, import duties & local taxes

Even for machines made locally, freight, handling and taxes can add 10–30 % (or more) to the base cost. - Service, warranty & spare parts

A vendor offering strong post-sales support, spare parts, warranty, and training will usually price higher. - Scale efficiencies & brand premium

An established brand or manufacturer with scale can negotiate better component costs, but may pass part of that premium to you for brand trust.

Buying Checklist – choosing the Right Nomatic Machine

To get the best fit (and avoid buyer’s remorse), run through this checklist:

- Production volume & cycle Time

Estimate hoe many parts/day you need and what cycle time is acceptable. - Short Size & mold Requirements

Ensure your parts size falls comfortably within the machines capacity (e.g30g,50g) . leave overhead for future tweaks. - Material Types

Some polymers (especially high-temperature ones) require better heating, storability, pressure pressure control-ensure the machine supports your chosen materials - Precision & Tolerances

If your parts demand tight dimensional tolerances, you may need higher grade cylinders cylinders, sensors, and structure rigidity. - Upgrade & Expansion Capability

Can you add features later (automatics, feeders, cooling, pickers)? Machine that allow modular upgrades offer better future flexibility. - Power & Utility Requirements

Check heck air compressors size, compressed air purity, power supply stability, cooling water, ect. - Vendor Support & Parts

Ensure that the vendor provides local service, spare parts availability, technical support, and some training. - Warranty & Terms

Try to negotiate at least 1 year warranty (or as per industry standards), plus support for breakdowns. - Total Cost of Ownership (TCO)

Don’t just consider upfront cost — also account for energy consumption, downtime, maintenance, spare parts, and depreciation. - Checks & Acceptance Testing

Before taking delivery or paying or full, run, test, parts, check tolerances, calibrate sensors, and see a trial run.

ROI & payback Estimation

Nomatic Molding Machine Price 2025 ROI to see whether such a machine is a worthy investment (example for Nomatic 50 g model):

- Machine price: ₹64,999 (base)

- Assumed additional cost (molds, installation, shipping): ₹20,000

- Total investment: ~ ₹85,000

Assume you produce a part that sells for ₹15, material + labor + overhead cost ₹8 → margin ₹7 per piece.

You target 10,000 parts/month → monthly margin = ₹70,000

Annual margin = ₹8,40,000

Subtract maintenance, consumables, servicing (say ₹1,20,000/year) → net incremental = ₹7,20,000

Payback = ₹85,000 / ₹7,20,000 ≈ 0.12 year (~1.5 months)

Of course, real world utilization might be lower, downtime will eat some margin, mold changes, waste, etc. But this example shows the strong potential of lower-cost machines if you keep operating costs tight. Nomatic Molding Machine Price 2025

Maintenance & Longevity Tips

To protect your investment, follow good maintenance practices:

- Clean periodic checks: air filters, valves, seals

- Lubrication: ensure sliding parts, joints, pneumatic cylinders are well-lubricated

- Air quality: supply clean, dry compressed air (remove moisture, oil)

- Component replacement: seals, O-rings, valves — change before complete failure

- Sensor calibration: periodically calibrate temperature, pressure, position sensors

- Mold care: rust protection, proper cooling, cleaning

- Spare parts: maintain a small inventory of critical wear parts

- Operator training: avoid abrupt overloads, misuse, or running outside specs

With good care, a Nomatic machine should comfortably serve 5–10 years or more in light-to-moderate duty settings.

Common Pitfalls & How to Avoid Them

- Choosing too small a machine: always build margin; do not run a machine at 100 % capacity indefinitely.

- Buying unnecessary features: don’t overpay for automation you don’t use.

- Ignoring mold quality: poor molds will ruin output regardless of how good machine is.

- Neglecting support / parts: downtime kills ROI faster than underutilization.

- Skimping on utilities: poor air, unstable power, lack of cooling will reduce performance.

- Failing to plan growth: pick a machine that can scale or upgrade instead of replacing.

Future Trends & Outlook (2025 & Beyond)

- More hybrid & servo-assisted pneumatic systems: combining the energy efficiency of pneumatic actuation with servo control will increase.

- Smart sensors & IoT integration: predictive maintenance, real-time monitoring, data logging will become standard.

- Better materials & nano-coatings: improved wear resistance, lower friction, reduced maintenance.

- Local manufacturing & cost competition: as Indian brands (like APS Star) increase quality, they may undercut importing brands for small/medium machines.

- Sustainability & energy efficiency: machines that optimize compressed air usage or recover energy will gain favor.

Given these, it’s wise to pick a Nomatic machine that allows modular upgrades and is compatible with future enhancements.

Table of Contents

Summary & Conclusion

- Nomatic Molding Machine Price 2025 are pneumatic / air-driven units suited for light-to-medium duty tasks.

- In 2025, APS Star offers 30 g and 50 g Nomatic machines at ₹49,999 and ₹64,999 respectively. APS Star Machine+2APS Star Machine+2

- Price depends on capacity, build quality, control systems, accessories, support, and logistics.

- Use a systematic checklist when buying — consider production volume, mold, material, precision, future needs, vendor support.

- Estimating ROI helps justify expenditure — many small machines pay back quickly if operated well.

- Maintenance, spare parts, and prevention are key to longevity.

- Avoid common pitfalls like undersizing, neglecting mold quality, or ignoring TCO.

- Watch trends — hybrid systems, IoT, and energy-efficient designs are shaping the next wave of molding machine tech.

If you like, I can generate a ready-to-publish HTML / WordPress version with images, alt tags, and internal links tailored to your existing site architecture — would you like me to do that?